Built to Withstand the Harshest Food & Beverage Environments

Precision, safety, and traceability are essential in the food and beverage (F&B) industry to ensure consistent product quality and meet stringent regulatory standards. NKK switches are designed to excel in the challenging environments of F&B production.

Our switches, including the SmartDisplay™ OLED Rocker, E-Stop, OLED Pushbuttons and Display, S331 Toggle, WR Rocker, M Series Dual Seal Toggle, and MRK Series Rotary, are engineered to thrive in environments with high humidity, water exposure, harsh chemicals, food particles, and strict cleaning protocols.

With features like IP68 and IP67-rated sealing, our switches deliver unmatched durability and precision, making them indispensable in hygiene-critical applications. Let’s explore real-world scenarios and the features that make these switches essential for F&B production.

1. SmartDisplay™ OLED Rocker: Your Recipe for Seamless Operations

The SmartDisplay™ OLED Rocker Switch revolutionizes human-machine interfaces (HMIs), offering real-time feedback and control for complex food processing lines.

Key Features:

- Dynamic OLED Display: Customizable, real-time operational feedback for functions like “Start,” “Pause,” and “Maintenance Mode.”

- Multi-Position Control: Streamlines workflows with easy switching between production states.

- Compact Design: Integrates seamlessly into equipment dashboards.

Applications:

- Operational State Management: Ideal for bottling and filling lines where quick adjustments are critical.

- Compliance and Safety: Pairs with dedicated Emergency Stop (E-Stop) switches for enhanced safety.

Real-World Example:

Bottling Station Overflow: When a filling station overflows, the operator uses the SmartDisplay™ OLED Rocker to pause operations, displaying “Filling Paused | Nozzle Overflow Detected” for fast resolution.

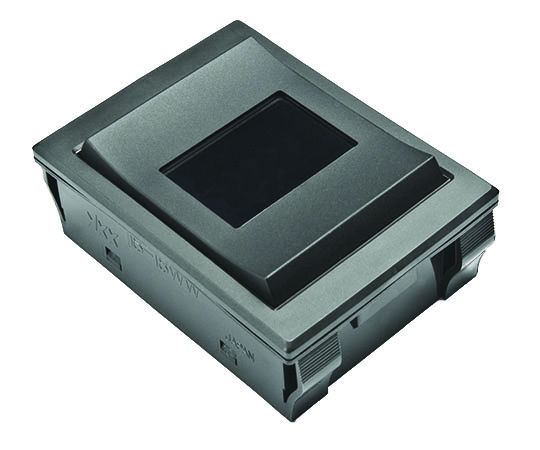

2. Emergency Stop (E-Stop): The Ultimate Safety Ingredient

NKK’s Emergency Stop switch ensures immediate power cutoff in critical situations, safeguarding equipment and personnel.

Key Features:

- Low-Profile Design: Compact 13.6mm behind-panel depth.

- Reliable Durability: Rated for 100,000+ actuations with twist or pull reset mechanisms.

- Optional Accessories: Available with switch guards and nameplates.

Applications:

- Emergency Shutdowns: Quickly disconnects power during malfunctions to prevent damage and ensure operator safety.

Real-World Example:

Conveyor Jam: When a conveyor line jams, the operator activates the E-Stop, halting operations. The SmartDisplay™ OLED Rocker provides diagnostics, displaying “Conveyor Jammed: Zone 3,” minimizing downtime.

3. M Series Dual Seal Toggle: Built for Safety in Harsh Environments

The M Series Dual Seal Toggle Switch is engineered for extreme conditions, delivering precision and resilience in food production environments.

Key Features:

- IP68 Sealing: Protects against contaminants and moisture.

- Extreme Temperature Resistance: Operates from -22°F to 185°F.

- Built for Washdowns: Withstands repeated sterilization cycles.

Applications:

- Ingredient Verification: Reliable toggle action for precise adjustments in production.

4. MRK Series Rotary: Precision and Compact Design

The MRK Series Rotary Switch offers low-profile durability with reliable detents for compact control panels.

Key Features:

- IP67 Rating: Designed for easy cleaning and harsh conditions.

- Wide Temperature Range: Performs reliably between 14°F and 158°F.

- Self-Cleaning Contacts: Gold-plated for consistent signal transmission.

Applications:

- Batch Adjustments: Precision control over mixing speeds, filling volumes, and temperature settings.

Streamline Your Workflow with NKK

NKK switches are tailored for the rigorous demands of the food and beverage industry. From advanced HMIs to manual controls, our innovative solutions enhance efficiency, safety, and productivity for success in your production line.