NKK provides Value Added Services to enhance our standard product offering and align with customer-specific requirements. A comprehensive offering of switch customization services is available from switch marking to wire harnesses and custom assemblies. Our Value Added facility is ISO:9001 certified, located in Scottsdale, Arizona, and uses only the most experienced operators to deliver high-quality products.

Customize Your Switch Assembly

Already Have Specific Requirements?

Already know exactly what you need? Fill out this form for custom specifications. It can be emailed directly to webemail@nkkswitches.com to expedite your order.

Explore More Services

Printing Services

NKK provides three capabilities for unique printing needs on plastic, metal, and painted products.

Screen Printing

- Excellent for printing flat surfaces

- Provides outstanding opacity

- Wide selection of colors

Pad Printing

- Excellent for irregular surfaces such as concave, convex or irregular

- Wide selection of colors

- Volume run capabilities

Laser Etching

- Permanent

- Etch outside and inside of cap

- High-volume capacity

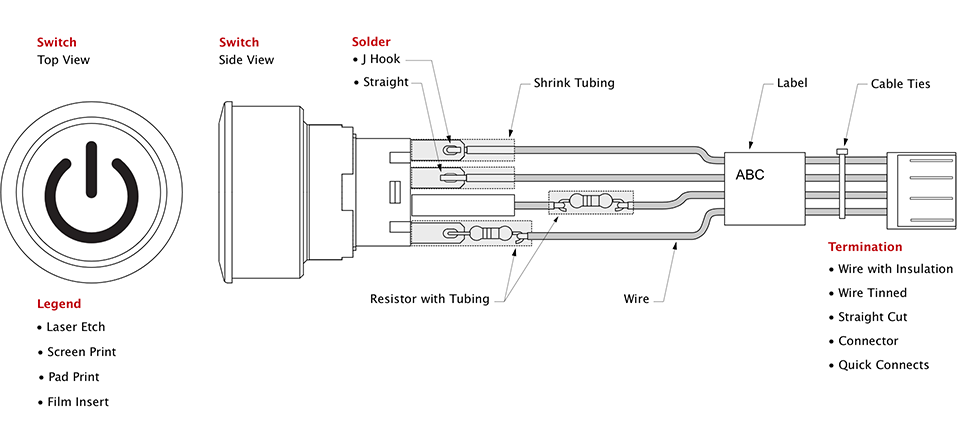

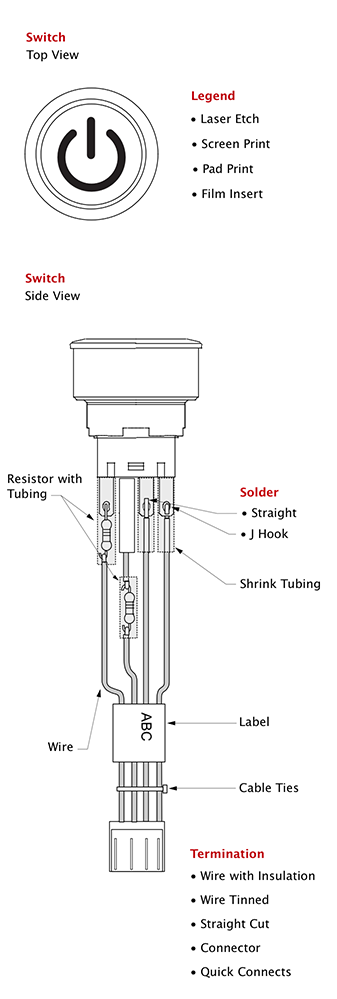

Custom Assembly Services

NKK partners with customers to understand their challenges, objectives and needs. This partnership leads to solutions that work.Electronic Assembly

- Surface mount, through-hole and PCB assembly

- Assemblers are highly trained, experienced and IPC-A-610 certified for surface mount and through-hole circuit card assembly

Electromechanical Assembly

(Including switch-based cable and wire harnesses)

- Assemblers are highly trained, experienced and IPC/WHMA-A-620 Certified

- UL recognized for wire harness assemblies

Connections & Special Materials

- Soldering and crimping

- Quick-connect terminations

- Heat shrink

- Epoxy

Download the Brochure

Value Added Services BrochureCertifications & Standards

ISO 9001:2015 – International Standard for Quality Systems

IPC-A-610 – International Quality Standard for Electronic Assembly

IPC/WHMA-A-620 – International Quality Standard for Cables & Wire Harnesses

UL Certified Wire Harnesses Program (UL File #E256736)

ESD Compliant – ANSI/ESD S20.20.2007

Request A Value Added Services Quote

Let NKK's Value Added Services design solutions for your unique printing and assembly challenges. Contact us to start your custom solution.

Value Added Products

NKK offers popular value added solutions as standard products for quick and easy order. Please check with an NKK Authorized Distributor for pricing and availability.